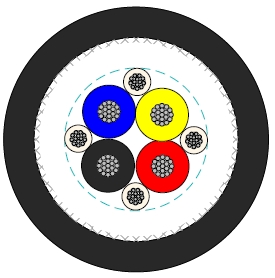

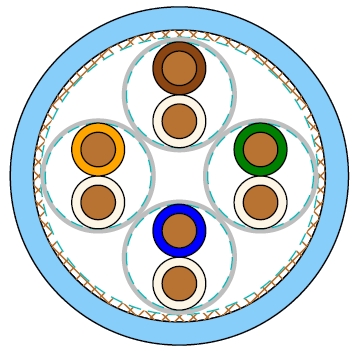

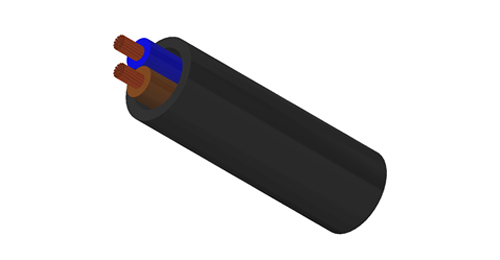

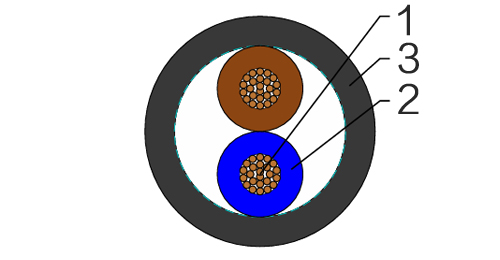

This is a flexible cable designed for light-duty environments , featuring excellent weather resistance, safety, and reliability . Specifically engineered for dry, damp, and even wet conditions both indoors and outdoors, it offers outstanding flexibility, oil resistance, and ozone resistance . It serves as a safe and cost-efficient solution for connecting electrical equipment and fixed installations.

CEI 20-19 p.4, CEI 20-35(EN 60332-1), CE low voltage directive 73/23/EEC & 93/68/EEC.,

IEC 60245-4, ROHS compliant

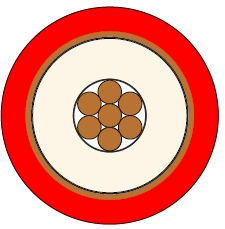

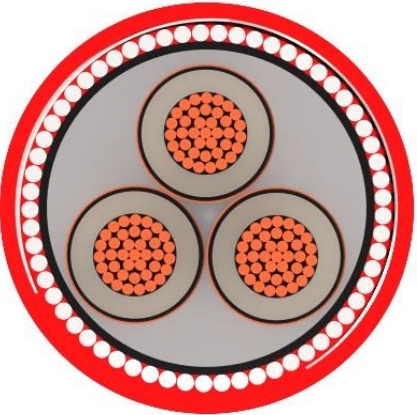

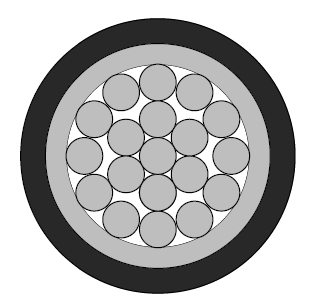

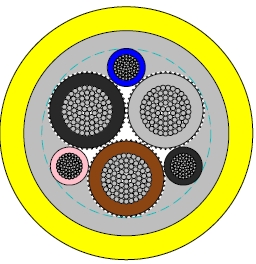

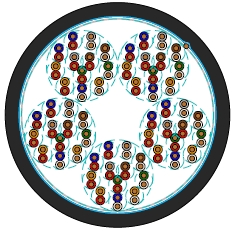

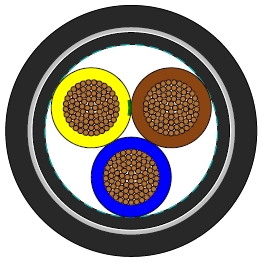

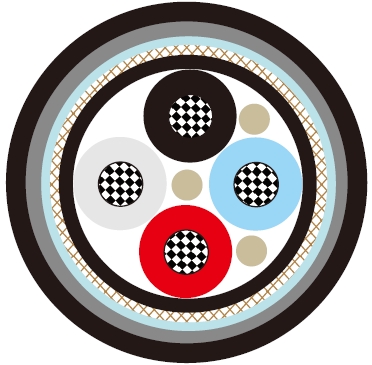

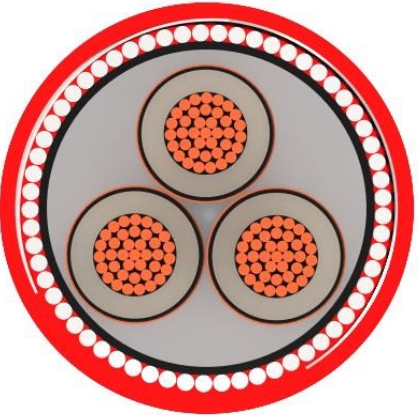

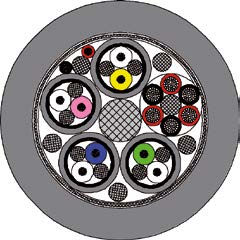

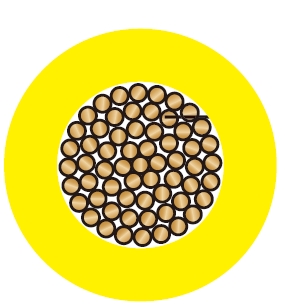

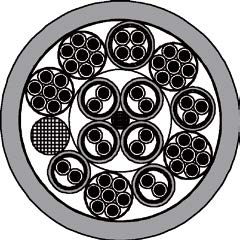

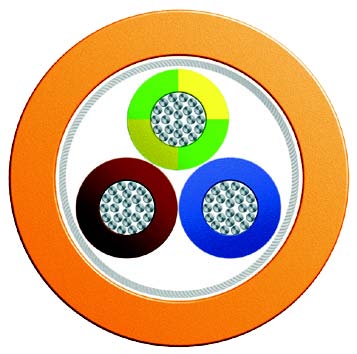

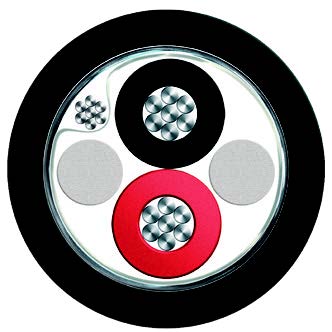

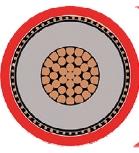

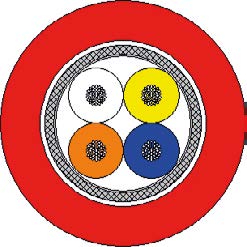

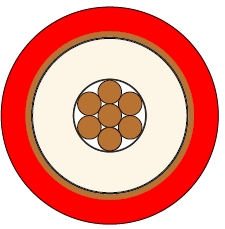

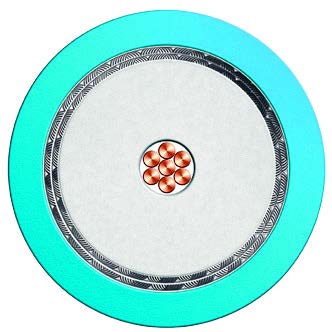

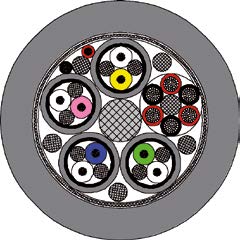

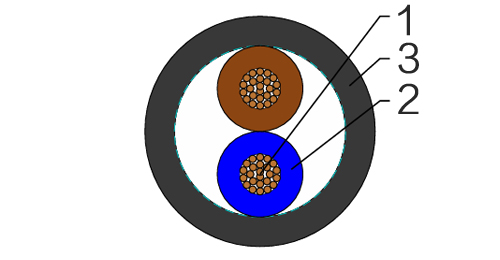

| Fine bare copper strands |

| Strands to VDE-0295 Class-5, IEC 60228 Class-5 |

| Rubber core insulation EI4 to VDE-0282 Part-1 |

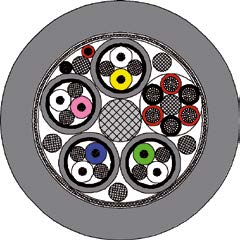

| Color code VDE-0293-308 |

| Green-yellow grounding, 3 conductors and above |

| Polychloroprene rubber (neoprene) jacket EM2 |

| Working voltage | 300/500 volts |

| Test voltage | 2000 volts |

| Flexing bending radius | 7.5 x O |

| Fixed bending radius | 4.0 x O |

| Temperature Range | -30oC to +60oC |

| Short circuit temperature | +200 oC |

| Flame retardant | IEC 60332.1 |

| Insulation resistance | 20 MΩ x km |

Technical Characteristics

| AWG | No. of Cores x Nominal Cross Sectional Area | Nominal Thickness of Insulation | Nominal Thickness of Sheath | Nominal Overall Diameter | Nominal Copper Weight | Nominal Weight |

| # x mm^2 | mm | mm | mm (min-max) | kg/km | kg/km | |

| H05RN-F | ||||||

| 18(24/32) | 2 x 0.75 | 0.6 | 0.8 | 5.7 - 7.4 | 14.4 | 80 |

| 18(24/32) | 3 x 0.75 | 0.6 | 0.9 | 6.2 - 8.1 | 21.6 | 95 |

| 18(24/32) | 4 x 0.75 | 0.6 | 0.9 | 6.8 - 8.8 | 30 | 105 |

| 17(32/32) | 2 x 1 | 0.6 | 0.9 | 6.1 - 8.0 | 19 | 95 |

| 17(32/32) | 3 x 1 | 0.6 | 0.9 | 6.5 - 8.5 | 29 | 115 |

| 17(32/32) | 4 x 1 | 0.6 | 0.9 | 7.1 – 9.2 | 38 | 142 |

| 16(30/30) | 3 x 1.5 | 0.8 | 1.0 | 8.6 - 11.0 | 29 | 105 |

| 16(30/30) | 4 x 1.5 | 0.8 | 1.1 | 9.5 - 12.2 | 39 | 129 |

| 16(30/30) | 5 x 1.5 | 0.8 | 1.1 | 10.5 - 13.5 | 48 | 153 |

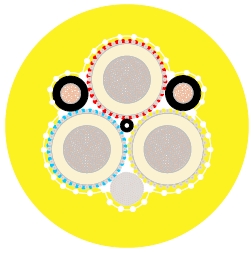

| H05RNH2-F | ||||||

| 16(30/30) | 2 x 1.5 | 0.6 | 0.8 | 5.25±0.15x13.50±0.30 | 14.4 | 80 |

| 14(50/30) | 2 x 2.5 | 0.6 | 0.9 | 5.25±0.15x13.50±0.30 | 21.6 | 95 |